We never offer our products or systems to customers without thoroughly verifying their functions and safety first. Our evaluation and analysis skills allow us to provide our customers with functional, safe products.

Product/ System evaluation

We prepare evaluation equipment and software specific to each of our products and systems, and confirm their functions under actual usage conditions and also under irregular conditions. Thus, we are able to provide our products with confidence.

Product/ System evaluation example

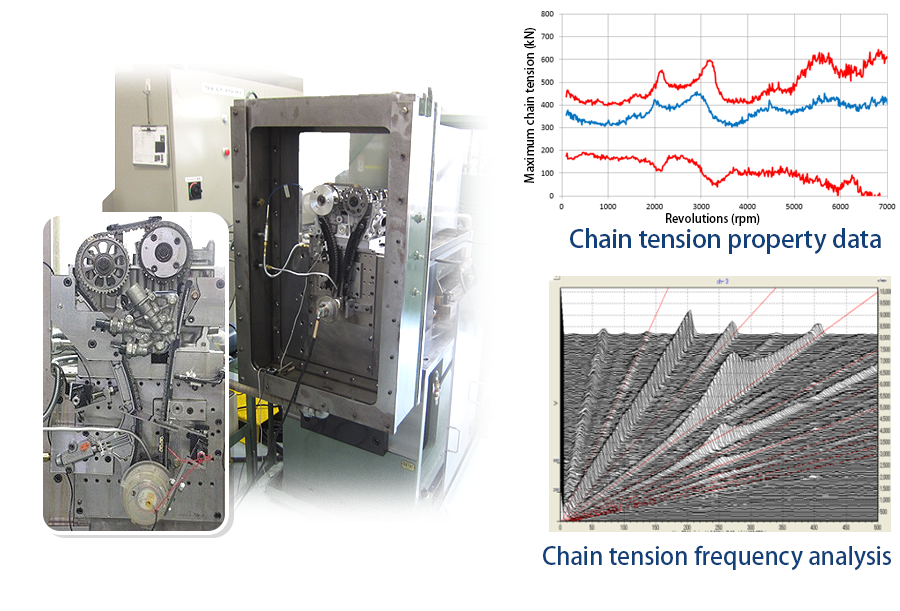

Car engine chain system evaluation

(1) System property evaluation (head simulation machine)

With the motoring test machine using an engine head, it is possible to directly observe and evaluate the cam chain. The test is not limited by the engine seal line: any type of chain can be evaluated and optimal configuration can be performed.

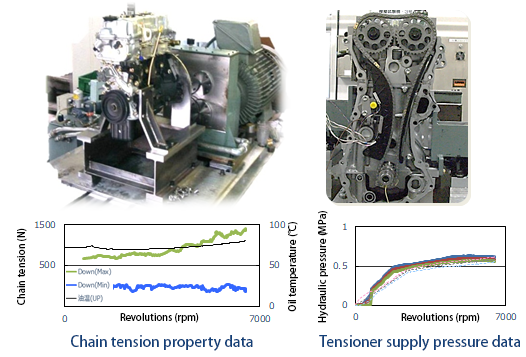

(2) System property evaluation (motoring testing machine)

The engine is driven by the motor. Thus, system products can be tested to evaluate their properties and durability under conditions similar to those of the actual machine.

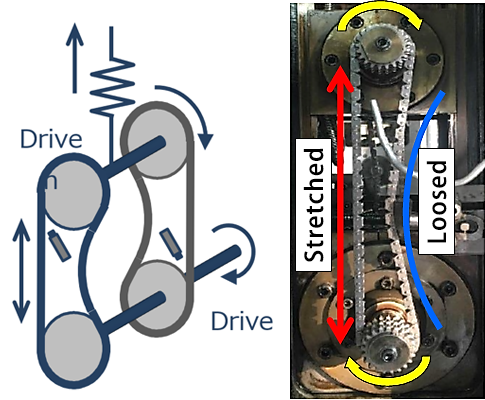

Chain performance evaluation (double-axis test machine)

Chain properties are tested using this machine. A load is applied to evaluate chain strength and abrasion resistance.

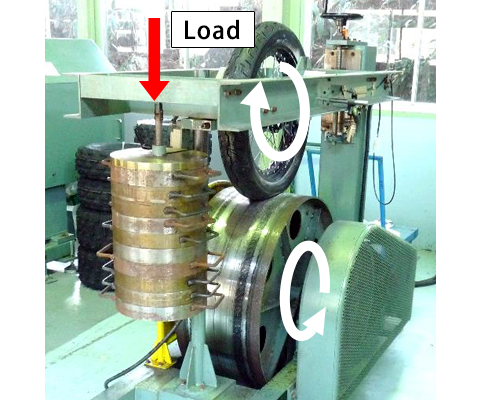

Wheel performance evaluation (drum durability test machine)

Load is applied in a radial direction to press a wheel with a tire onto a drum rotating at a constant speed. The wheel’s fatigue durability is tested on the assumption that vertical load is applied repeatedly to a wheel while running straight.

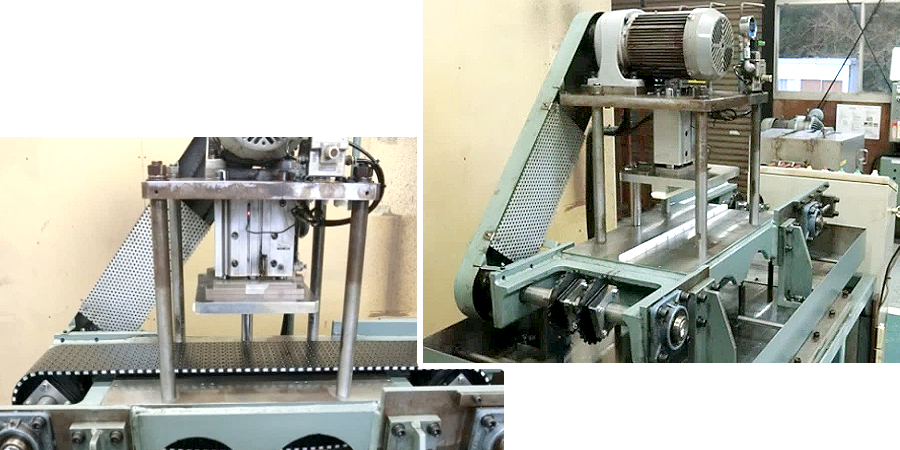

Transfer function evaluation (transfer chain test machine)

Plastic chains’ sliding properties and rollers’ revolution resistance are tested on the assumption that a transported object is placed on the chain.

High-temperature durability evaluation (furnace test machine)

The durability of chains used at high temperature is tested in a furnace that can be heated to 750ºC, and their operation at high temperature is evaluated.

Property analysis/ Measurement

We possess equipment to analyze, examine and measure various elements to evaluate our products and systems; thus, we are able to respond to customers’ requests promptly and assure product quality and safety.

Analysis/ Measurement examples

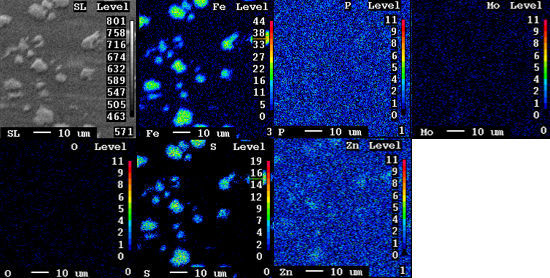

Element analysis

An electron probe micro analyzer (EPMA) is used to radiate electron beams onto specimen surfaces in a vacuum and analyze the produced characteristic X-rays, thus identifying elements and measuring their amounts.

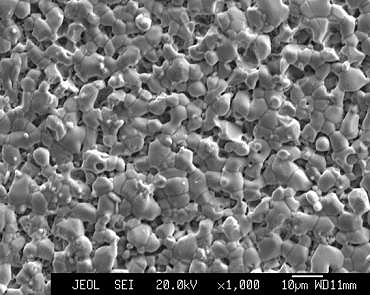

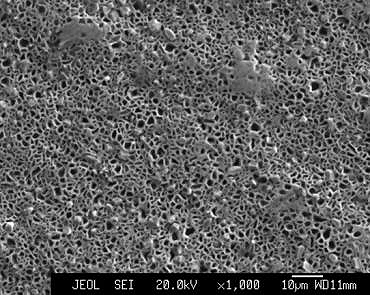

Surface structure observation

A scanning electron microscope (SEM) is used to obtain high-precision images at high magnification rates from a few nanometers to a few microns, thus enabling detailed observation of specimen surfaces.

Molecule structure analysis

Fourier transform infrared spectroscopy (FT-IR) is used to irradiate specimens with infrared rays and measure the transmitted and reflected IR spectrums. The measured data is compared against a database to identify compounds.